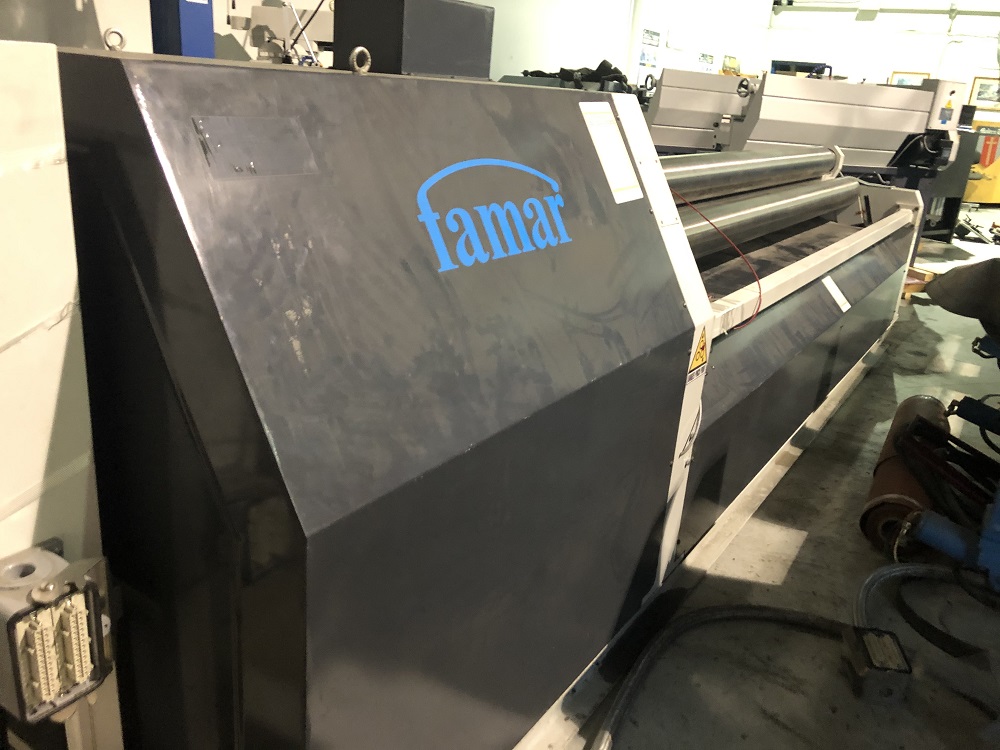

Description

STANDARD FEATURES

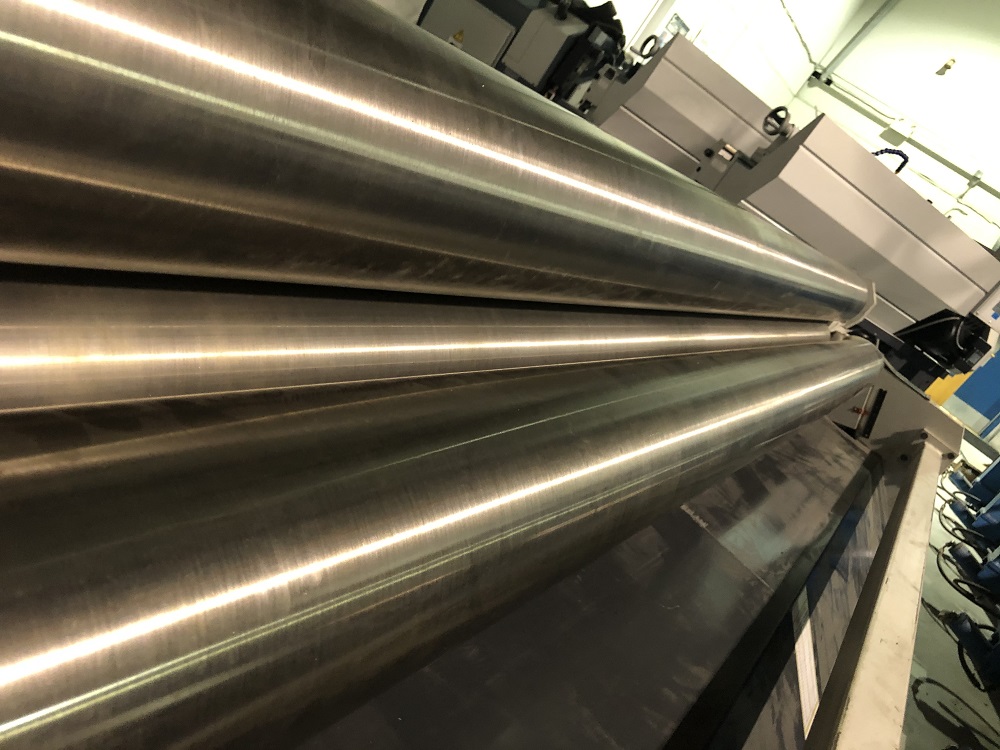

- Both upper roll and central pinch rolls driven by electric motor and oil bath speed reducer through NiCrMo solid stock gears

- Base in steel, electro-welded and stress relieved

- Lateral roll, idle and moving on roller bearings

- Pinch roll pinch pressure adjustable by precision worm gear movement

- Yoke type drop end for top toll release, manual, for part removal

- Top roll lifting via hydraulic jack, manual, further facilitates part removal

- Lateral roll movement via electric motor and heavy duty worm gear drive for precise positioning and maximum power

- Lateral bending roll and pinch roll incline for cone working

- Low voltage push button controls via mobile control console

- Multi point safety system including circumferential trip wire

- Forced lubrication system

- Instruction manual

BENDING CAPACITIES (* at full roll width)

- Useful length maximum: 120”

- Rolling thickness maximum: 12 gauge

- Pre bending thickness maximum: 14 gauge

- Minimum diameter obtainable with thinner sheets 1.4 times top toll diameter allowing for material spring back – data calculated using certified mild steel yield point of 36,000 psi

OPTIONAL EQUIPMENT

- Induction hardened rolls, required for most applications

- Polished roll surfaces for bright or polished materials

- Cone rolling attachment

- Hydraulic powered drop end & top roll suspension

- 2 LED readouts with position preset for lateral rolls (1 each roll)

- 1 LED readout on pinch roll

- LED readout on roll rotation (material translation) with memory preset